|

|

|

|

|

|

|

CNG-R Concept for Motorsport Applications

fig. 1.1 CNG Mitsubishi Gr.A rally car, successfully competing in the Austrian Rally Championship

fig. 1.1 CNG Mitsubishi Gr.A rally car, successfully competing in the Austrian Rally Championship

|

1. Introduction

In order to meet expectations from modern motorsports regarding emissions and other general environmental aspects, back in 2006 Stohl Racing started a project together with OMV (Austrian Minerals Federation), to get not only rally sports greener. The basic idea behind these following efforts was to develop a powerful engine package which uses compressed natural gas instead of classic petrol, and is evenly competitive while emitting much less harmful substances.

2. Basic Structure

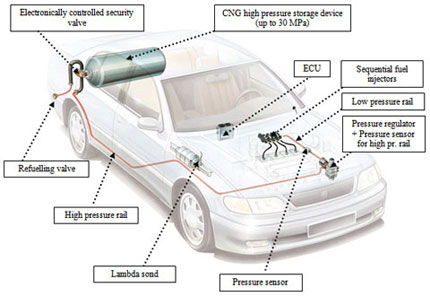

fig. 1.2 Basic CNG system for a road going car

fig. 1.2 Basic CNG system for a road going car

|

3. Stohl Racing Concept

As commonly used systems for OEM vehicles, and aftermarket conversions intended for daily use road going vehicles are neither reliable, nor powerful enough to withstand the abuse caused at racing circumstances (especially in rallies) and to ensure the competitiveness of the car they are applied to, a lot of research and development work had to be done to construct a system meeting the above requirements. The following points are only an overview, listing the main points of our motorsport dedicated CNG-R system.

- Monovalent concept

Instead of using a bivalent concept, by means of the existence of a low volume petrol tank for starting purposes, besides the regulation requirements, it was clear for us that a true CNG race system must be able to work without any use of other energy storing fluids.

- Sequential injection

While many systems are realised, by adding 1 single injector to supply the necessary amount of CNG to all cylinders, the high levels of accuracy needed in racing applications exclude such a structure. As a conclusion, we decided the use of 1 injector per cylinder.

- Electronically controlled pressure regulator

In order to have full control over the rail pressure, thus being able to compensate this depending on nearly all process influences, the use of a PID controlled pressure regulator was indispensable.

- Type 4 CNG cylinders

To reach the lowest possible weight, whilst still meeting highest security standards, we exceptionally use Type 4 (no usage of metallic materials) storage devices.

- MoTeC ECU

While often an additional ECU is used to control the CNG system only, our system utilizes 1 single control unit for all engine processes, resulting in a user friendly and reliable control system. Being a MoTeC unit, it ensures full control over all necessary functions needed to run a race car.

4. Application Overview

The following list gives an overview of applications developed by us.

-

Mitsubishi Evolution VI CNG Gr.A

Development prototype

First overall victory for a CNG powered car at the 2007 Ostarrichi Rally

fig. 4.1 Evolution VI CNG in action

fig. 4.1 Evolution VI CNG in action

|

-

Mitsubishi Evolution IX CNG Gr.A

Overall victory at the 2008 Waldviertel Rally

Several Top 3 results in the 07 and 08 seasons of the Austrian Rally Championship

fig. 4.2 Evolution IX CNG at refuelling

fig. 4.2 Evolution IX CNG at refuelling

|

-

Subaru Impreza STI 07 CNG Gr.N

First competition of the new Gr.N regulation CNG system

Finished 4th overall in all first competition and set best times in several SS

Vice champion in austrian national championship 2009, placed in between 2 S2000s

fig. 4.3 Subaru Gr.N at the 09 Jaennerrally

fig. 4.3 Subaru Gr.N at the 09 Jaennerrally

|

fig. 4.4 Fuel cell installation; Subaru STI 07

fig. 4.4 Fuel cell installation; Subaru STI 07

|

|

|

|

|

|

|

|

|

|